JPCP Restoration

Existing JPCP restoration sometimes referred to as zero-thickness JPCP repairs is a rehabilitation design option considered by PMED for an existing JPCP only. Typically, JPCP restoration is done to improve its structural adequacy and ride quality in the short to medium term.

For PMED, existing JPCP restoration is defined as diamond grinding and any combination of the following repair treatments (1) joint load transfer restoration, (2) retrofit edge drains, (3) full-depth repairs, (4) slab replacement, and (5) shoulder replacement. Properly designed and constructed restoration treatments do reduce future pavement deterioration and prolong life. However, JPCP restoration performance also depends on the combination of restoration treatments applied.

General Design Inputs

A JPCP Restoration addresses cases where an existing JPCP is restored to improve its structural adequacy and ride quality for carrying additional traffic.

The following options allow you to establish the basic parameters of your project.

Ways to Access this Interface

Open a new pavement project. The General Information area appears at the top-left corner of the Project Tab.

Figure 807: General Information

Populating the Inputs for this Interface

Design type: Select Overlay

Pavement type: Select JPCP Restoration

In addition to selecting Design and Pavement type, select values for the following basic design parameters:

Design life (years): This control allows you to select from a list the period of time in years the restored JPCP is expected to perform.

Existing construction: This control allows you to select the month and year when the construction of existing JPCP was completed.

Pavement construction: This control allows you to select the month and year when the restoration of existing JPCP is scheduled.

Traffic opening: This control allows you to select the month and year the restored pavement is scheduled to be open to traffic. PMED predicts pavement performance beginning from this month and year.

Performance Criteria

Performance verification forms the basis for determining the adequacy of a trial design. Adequacy for PMED implies that the trial design meets all performance criteria at a user or agency selected level of reliability within the trial pavements design life or the PMED analysis period. If the trial design after analysis does produce distress/smoothness levels in excess of the user or agency threshold levels, then the trial design must be modified to produce more acceptable levels of distress and smoothness. Trial design modification includes changes to JPCP design features. In general, trial design site properties such as climate, traffic, material properties and foundation/subgrade type cannot be altered to improve design adequacy.

The distress types considered in JPCP restoration design are transverse “slab” cracking and transverse joint faulting. In addition, PMED predicts transverse joint spalling which is used solely as an input for predicting smoothness characterized using the International Roughness Index (IRI).

Figure 808: Performance Criteria

Populating the Inputs in this Interface

This table allows you to define the limits or threshold values of distresses and smoothness that are used by PMED to define performance. The limits of distresses and smoothness must be specified at a user/agency reliability level to make them meaningful. The limits of distresses and smoothness must be seen as upper boundary levels within an acceptable range. PMED goes not require lower boundary levels for distresses as they are assumed to be zero immediately after JPCP restoration. For smoothness/IRI, however, the lower boundary level is never zero and mostly ranges from 30 to 70 in/mi. As the smoothness/IRI lower boundary level cannot be assumed to be zero, PMED allows for user-specific input for this parameter, which it calls initial IRI.

This table has three columns:

Performance Criteria: This column provides a list of performance indicators required to ensure that the restoration of JPCP will perform satisfactorily over its design life.

Limit: This column allows you to define the threshold values of these performance indicators to evaluate the adequacy of a restoration design.

Reliability: This column allows you to define the probability at which the predicted distresses and smoothness will be less than the limits over the design period.

Note:

You can override the program defaults to enter project-specific threshold limits and reliability values representing agency policies. Refer to Chapter 8 of the AASHTO Manual of Practice for more guidance on selecting design criteria and reliability level.

Initial IRI (in. /mile): The limit control allows you to define the level of smoothness immediately after restoration (expressed in terms of IRI). Initial IRI is a very important input as the time from initial construction to attaining threshold IRI value is very much dependent on the initial IRI obtained at the time of construction. Thus, the initial IRI value provided must be what is typically attained in the field. You can override the PMED default value of 63 in. /mi to reflect agency policy and guidelines.

Terminal IRI (in. /mile): The limit and reliability controls allow you to define the threshold value for IRI at the end of the design life at a user or agency specified reliability level.

Mean joint faulting (in.): The limit and reliability controls allow you to define the threshold value for transverse joint faulting at the end of the design life at a user or agency specified reliability level. Transverse joint faulting is the differential elevation across the transverse joint measured approximately 1 ft from the slab edge (longitudinal joint for a conventional lane width), or from the rightmost lane paint stripe for a widened slab. Since joint faulting varies significantly from joint to joint, the mean faulting of all transverse joints in a pavement section is the parameter predicted by the PMED.

JPCP transverse cracking (percent slabs): The limit and reliability controls allow you to define the threshold value for transverse cracking at the end of the design life at a user or agency specified reliability level. PMED predicts the combined percentage of PCC slabs with bottom-up and top-down transverse cracks that occurs mostly in the middle third of the slab. It is reported as percent slabs cracked. A description of the two main transverse cracking mechanisms are described below:

Bottom-up transverse cracking: When the truck axles are near the longitudinal edge of the slab, midway between the transverse joints, a critical tensile bending stress occurs at the bottom of the slab under the wheel load. This stress increases greatly when there is a high positive temperature gradient through the slab (the top of the slab is warmer than the bottom of the slab). Repeated loadings of heavy axles under those conditions result in fatigue damage along the bottom edge of the slab, which eventually result in a transverse crack that propagates to the surface of the pavement.

Top-down transverse cracking: Repeated loading by heavy truck tractors with certain axle spacing when the pavement is exposed to high negative temperature gradients (the top of the slab cooler than the bottom of the slab) result in fatigue damage at the top of the slab, which eventually results in a transverse or diagonal crack that is initiated on the surface of the pavement. The critical wheel loading condition for top-down cracking involves a combination of axles that loads the opposite ends of a slab simultaneously. In the presence of a high negative temperature gradient, such load combinations cause a high tensile stress at the top of the slab near the critical pavement edge. This type of loading is most often produced by the combination of steering and drive axles of truck tractors and other vehicles. Multiple trailers with relatively short trailer-to-trailer axle spacing are other common sources of critical loadings for top-down cracking.

Pavement Structure

This section explains adding additional layers to a pavement, editing the properties of those layers, and working with the pavement structure as a whole.

PCC (Existing Intact JPCP) Layer

Methods to Populate Inputs

There are two methods for entering data for the Portland Cement Concrete layer:

- Manual entry

- Import from workspace library

Inputs

PCC

- Thickness (in.): This control allows you to define the thickness of the PCC layer used in the trial design. Note that this input has a significant impact on PMED prediction of future JPCP performance.

- Unit weight (pcf): This control allows you to define the weight per unit volume of the PCC mix design. Typical values ranges from 140 to 160 pcf.

- Poisson’s ratio: This control allows you to define the PCC’s Poisson’s ratio (defined as the ratio of PCC lateral and longitudinal strain under applied loading). Poisson’s ratio is an important input required for structural analysis. Values between 0.15 and 0.18 are typical PCC used in JPCP construction.

Thermal

- PCC coefficient of thermal expansion (in/in/deg F x 10-6): This control allows you to define the expansion or contraction a material undergoes with change in temperature. PCC coefficient of thermal expansion (CTE) is defined as the increase in length per unit length of PCC (typically 1-in) for a unit increase in temperature (typically 1 ˚F). PCC CTE has a significant impact on critical curling stresses developed in the JPCP PCC slab and thus the development of transverse cracks. PCC CTE can be considered to be a very critical input that influences the development of transverse cracking.

- PCC thermal conductivity (BTU/hr-ft-deg F): This control allows you to define the ability of the PCC material to uniformly conduct heat through its thickness when subjected to a temperature differential at the top surface and bottom of the PCC layer. PMED provides a typical value of 1.25 BTU/hr-ft-˚F.

- PCC heat capacity (BTU/lb-deg F): This control allows you to define the amount of heat required to raise a unit mass of PCC material (typically 1 Ib) by a unit temperature (typically 1 ˚F). PMED provides a typical value of 0.28 BTU/hr-ft-deg F.

Note:

The CTE should be adjusted as follows to reflect the CTE values used to calibrate the current models . CTE input =CTEpcc – CTEcalib + 9.6110-6 in/in/ ˚F CTEinput = CTE adjusted to reflect CTE values used in calibration, in/in/ ˚F CTEpcc = CTE of concrete specimen according to AASHTO T 336 or TP 60, in/in/ ˚F CTEcalib = CTE of 304 stainless steel calibration or verification specimen used to determine CTEpcc, in/in/ ˚F CTE values contained in the LTPP Standard Data Release 24.0 dated January 2010 or later have been updated with this correction. These CTE values should be increased by 0.8310-6 in/in/ ˚F if they are used as a level 3 input. CTE values prior to LTPP SDR 24.0 do not need to be adjusted.

Mix

-Cement type: This control allows you to select the type of cement used in the PCC mix. PMED allows you to select one of the following Portland cement types: - Type I: Type I cements are described as general purpose cements suitable for most pavement construction situations where special properties such as high early strength, high durability, etc., are not required. - Type II: Type II cements contain no more than 8% tricalcium aluminate (C3A) and are suitable for situations where moderate sulfate resistance is required. - Type III: Type III cements have constituents very similar to Type I cements. However, the constituents are ground to produce a finer mix that produces higher levels of early strengths. Thus, Type II cements are generally used in JPCP construction where early strength is required.

Note:

For PCC mixes with non-conventional cement types, select the cement type provided by PMED which is closest in characteristics.

-Cementitious material content (lb/yd3): This control allows you to define the total weight of cementitious material (portland cement, pozzolans, lime, fly-ash, etc.) per unit volume of PCC as per the PCC mix design. The cementitious material along with water content is used to calculate PCC ultimate shrinkage, a critical parameter in structural analysis.

Water to cement ratio: This control allows you to define the ratio of the weight of water to the weight of all cementitious materials used in the PCC mix design. This input is used to calculate the water content of the PCC mix and is used along with cementitious material content to calculate PCC ultimate shrinkage, a critical parameter in structural analysis.

Aggregate type: This control allows you to select the coarse aggregate rock type in the PCC mix. If the coarse aggregate rock type is not uniform, the predominant rock type must be selected. Coarse aggregate is typically described as the material the material retained on the No. 4 sieve. Coarse aggregate rock type is used to calculate PCC ultimate shrinkage. PMED allows you select one of the following coarse aggregate rock types:

Quartzite: This option allows you to select quartzite as the predominant coarse aggregate rock type in the PCC mix. Quartzite is a metamorphic rock which is extremely resistant to weathering and erosion.

Limestone: This option allows you to select limestone as the predominant coarse aggregate rock type in the PCC mix. Limestone is a sedimentary rock composed largely calcium carbonate and provides a solid base for highway pavements.

Dolomite: This option allows you to select dolomite as the predominant coarse aggregate rock type in the PCC mix. Dolomite is a sedimentary carbonate rock composed mainly of calcium magnesium carbonate. Dolomite like limestone provides a solid base for highway pavements.

Granite: This option allows you to select granite as the predominant coarse aggregate rock type in the PCC mix. Granite is an intrusive, felsic, igneous rock and is extremely resistant to weathering and erosion.

Rhyolite: This option allows you to select rhyolite as the predominant coarse aggregate rock type in the PCC mix. Rhyolite is an igneous, volcanic (extrusive) rock and is extremely resistant to weathering and erosion.

Basalt: This option allows you to select basalt as the predominant coarse aggregate rock type in the PCC mix. Basalt is an extrusive igneous rock and is extremely resistant to weathering and erosion.

Syenite: This option allows you to select syenite as the predominant coarse aggregate rock type in the PCC mix. Syenite is a coarse-grained intrusive igneous rock of the same general composition as granite but with the quartz either absent or present in relatively small amounts. Syenite is extremely resistant to weathering and erosion.

Gabbro: This option allows you to select gabbro as the predominant coarse aggregate rock type in the PCC mix. Gabbro is an intrusive mafic igneous rock, rich in iron and magnesium, poor in silica (quartz) and chemically equivalent to basalt. Gabbro is extremely resistant to weathering and erosion.

Chert: This option allows you to select chert as the predominant coarse aggregate rock type in the PCC mix. Chert is a sedimentary rock widely used in highway pavement construction. It is moderately resistant to weathering and erosion.

PCC set temperature (deg F): This control allows you to define the PCC temperature when the freshly placed PCC slab becomes solid. PCC set temperature can be user entered or estimated by PMED using (1) average of hourly ambient temperatures for month of construction and (2) cementitious material content. The default for this control is to let PMED calculate the PCC set temperature. You can, however, override the PMED default and enter your own PCC set temperature.

Calculated internally? This control allows you to decide whether PMED should calculate PCC set temperature or not by selecting one of the following options:

True: Selecting this option allows PMED to calculate the PCC set temperature.

False: This option allows you to input directly PCC set temperature.

User-specified PCC set temperature: This control allows you define the PCC set temperature in degrees Fahrenheit (minimum 70, maximum 212).

Ultimate shrinkage (microstrain): This control allows you to define the ultimate (long-term) shrinkage strain that PCC will develop under laboratory controlled conditions of temperature and humidity (e.g., 40% relative humidity). The default for this control is to let PMED calculate PCC ultimate shrinkage internally. You can, however, override the PMED default and enter your own PCC ultimate shrinkage.

Calculated internally? This control allows you to decide whether PMED should calculate PCC ultimate shrinkage or not by selecting one of the following options:

True: Selecting this option allows PMED to calculate the PCC ultimate shrinkage.

False: This option allows you to input directly PCC ultimate shrinkage.

User-specified PCC ultimate shrinkage: This control allows you define the PCC ultimate shrinkage in microstrain (minimum 300, maximum 1000).

Reversible Shrinkage (%): Change in PCC humidity/moisture affects the volume of PCC with moisture causes PCC expansion while drying causes PCC shrinkage. Note that this is very different from the drying shrinkage in PCC due to moisture loss during PCC hardening that result in irreversible shrinkage. This control allows you to define the percent of PCC ultimate shrinkage that can be recovered due to changes in PCC humidity/moisture (minimum 0, maximum 100).

Time to develop 50% of ultimate shrinkage (days): This control allows you to define the time required in days to develop 50% of PCC ultimate shrinkage (minimum 30, maximum 50).

Curing method: This control allows you to select curing method applied after PCC placement. PMED allows you to select one of the following options:

Wet Curing: These are curing methods that prevent PCC surface moisture loss by supplying additional water to the PCC surface. The most common practice is to place wet burlap or other natural or synthetic-fiber blankets at the PCC surface to prevent rapid evaporation of moisture. Selecting this option implies the use of the above listed methods or similar techniques for PCC curing.

Curing Compound: These are curing methods that prevent moisture loss at the PCC surface by placing a liquid membrane-forming chemical compound (typically resins, waxes or synthetic rubbers dissolved in a solvent) that forms a near-impermeable membrane over the PCC once the solvent evaporates. Selecting this option implies the use of the above listed methods or similar techniques for PCC curing.

Strength

PMED requires both PCC modulus of rupture and elastic modulus.

PCC strength input level: This control allows you to select modulus of rupture and elastic modulus input level. PMED allows for the following options:

Level 1: This option allows you to directly input the 7-, 14-, 28-, and 90-day PCC elastic modulus and modulus of rupture. For this option, the 20-yr and 28-day PCC elastic modulus and modulus of rupture ratios are also required.

Level 2: This option allows you to directly input the 7-, 14-, 28-, and 90-day PCC compressive strength. For this option, the 20-yr and 28-day PCC compressive strength ratio is also required.

Level 3: This option allows you to directly input any of the following combination of inputs:

28-day PCC modulus of rupture only.

28-day PCC compressive strength only.

28-day PCC modulus of rupture and 28-day PCC elastic modulus.

28-day PCC compressive strength and 28-day PCC elastic modulus.

Level 1 Modulus of Rupture/Elastic Modulus Table: This table allows you to define modulus of rupture and elastic modulus of the existing PCC layer:

Time: This column lists the age of the existing PCC layer at which the AC overlay is placed. The age is computed internally by PMED using the existing construction date and pavement (rehabilitation) construction date.

Modulus of Rupture (psi): This column allows you to define PCC modulus of rupture of the existing PCC layer.

Elastic Modulus (psi): This column allows you to define the elastic modulus of the existing PCC layer. The backcalculated “dynamic” elastic modulus values must be adjusted to “static” values. Refer to the AASHTO Manual of Practice for guidance.

User-defined Modulus Adjustment Factor: This control allows you enter an adjustment factor to convert backcalculated dynamic modulus to static modulus.

Figure 810: PCC Strength 1

Level 2 Compressive Strength Table: This table allows you to define the compressive strength of the existing PCC layer:

Time: This column lists the age of the existing PCC layer at which the AC overlay is placed. The age is computed internally by PMED using the existing construction date and pavement (rehabilitation) construction date.

Compressive strength (psi): This column allows you to define the compressive strength of the existing PCC layer.

Figure 811: PCC Strength 2

- Level 3 Modulus of Rupture, Compressive Strength, and Elastic Modulus Table: This control allows you to define your preferred combination of PCC strength and elastic modulus inputs at Level 3. PMED allows for the following combination of inputs by checking the appropriate radio button and check box:

- 28-day PCC modulus of rupture only.

- 28-day PCC compressive strength only.

- 28-day PCC modulus of rupture and 28-day PCC elastic modulus.

- 28-day PCC compressive strength and 28-day PCC elastic modulus.

Figure 812: PCC Strength 3

Asphalt Concrete Base Layer

Methods to Populate Inputs

There are two methods for entering data for the Asphalt Concrete layer:

- Manual entry

- Import from workspace library

Inputs

Asphalt

- Thickness (in): This control allows you to define the thickness, in inches, of the selected layer.

Mixture Volumetrics

- Unit weight (pcf): This control allows you to define the weight of the selected material in pounds per cubic foot.

- Effective binder content (%): This control allows you to define the effective binder content of the asphalt concrete mixture.

- Air Voids (%): This control allows you to define the percent volume of air voids in the as-constructed asphalt concrete pavement layer.

- Poisson’s ratio: This control allows you to define the Poisson’s ratio of the material in two ways: a constant value (Level 3) or calculate as a function of dynamic modulus (Level 2). Clicking the plus sign (+) to the left of this control presents the following options:

- Is Poisson’s ratio calculated?: Select True to calculate Poisson’s ratio as a function of dynamic modulus. Select False to use a constant value.

- Poisson’s ratio: This control allows you to define a constant value of Poisson’s ratio .This control is disabled when you select True.

- Poisson’s ratio Parameter A: This control allows you to define the parameter A of the Poisson’s ratio model. You can override the default value of -1.63 to enter mixture-specific values. This control is disabled when you select False.

- Poisson’s ratio Parameter B: This control allows you to define the parameter B of the Poisson’s ratio model. You can override the default value of 3.84E-06 to enter mixture-specific values. This control is disabled when you select False.

Note:

Parameters A and B are the empirical coefficients of the predictive model that defines Poisson’s ratio as a function of dynamic modulus, as described in the AASHTO Manual of Practice.

Mechanical Properties

- Dynamic modulus input level: This control allows you to define the level of inputs for dynamic modulus of asphalt concrete material. Select one of the following options from the dropdown menu:

- Level 1: Selecting 1 gives you the option to input directly the laboratory tested dynamic modulus properties of the asphalt concrete mixture and laboratory tested asphalt binder properties. These are described in the AASHTO Manual of Practice as Level 1 inputs.

- Level 2: Selecting 2 gives you the option to derive dynamic modulus properties from laboratory tested asphalt binder properties and the aggregate gradation of the asphalt concrete mixture. These are described in the AASHTO Manual of Practice as Level 2 inputs.

- Level 3: Selecting 3 gives you the option to derive dynamic modulus properties from typical rheological properties of the asphalt binder grade you select and the aggregate gradation of the asphalt concrete mixture. These are described in the AASHTO Manual of Practice as Level 3 inputs.

Note:

Input screens for dynamic modulus and AC binder properties change with the input level selected. For example, the input screen for dynamic modulus properties at level 1 is different from those at levels 2 and 3, while for asphalt binder properties, the input screens at levels 1 and 2 are different from that of Level 3.

Dynamic Modulus

Dynamic Modulus Input Level 1

This control allows you to define the Level 1 dynamic modulus values of the asphalt concrete mixture.

Figure 814: Dynamic Modulus Level 1

- Select temperature level: This control allows you to define the number of test temperatures at which the dynamic modulus values is provided for a given mixture.

- Select frequency level: This control allows you to define the number of test frequencies at which the dynamic modulus values is provided for a given mixture.

- Temperature (deg F): This control allows you to define the temperature at which the dynamic modulus values were measured for a given mixture. You should enter at least one input value less than 30˚F, another in the range of 40 to 100˚F, and the third input value higher than 125˚F.

- Frequency (Hz): This control defines the test frequency at which the dynamic modulus values were measured for a given mixture. You should enter at least one input value less than 1 Hz, two in the range of 1-10 Hz and the fourth input value higher than 10 Hz.

You can populate the cells within the dynamic modulus table provided with corresponding dynamic modulus values for the user-defined temperature and frequency levels. PMED provides default temperatures of 14, 40, 70, 100 and 130˚F, and default frequencies of 0.1, 1, 10 and 25 Hz.

Note:

Input screens for dynamic modulus and AC binder properties change with the input level selected. For example, the input screen for dynamic modulus properties at level 1 is different from those at levels 2 and 3, while for asphalt binder properties, the input screens at levels 1 and 2 are different from that of Level 3.

Right-Click Menu Options

Right-click on a cell in the dynamic modulus table to access the following functionality:

- Copy: This menu item copies the selected value.

- Paste: This menu item pastes the copied value.

- Import MEPDG Dynamic Modulus (.dwn) Format: This menu item allows you to import a dynamic modulus file that was created in using MEPDG.

Dynamic Modulus Input Levels 2 and 3

This control allows you to define the aggregate gradation of the asphalt concrete mixture for use in dynamic modulus calculations.

Figure 815: Dynamic Modulus Level 2 and 3

- 3/4-inch sieve: This control allows you to define the cumulative amount of aggregate material (used in the asphalt mixture) that is passing on the ¾ inch sieve.

- 3/8-inch sieve: This control allows you to define the cumulative amount of aggregate material (used in the asphalt mixture) that is passing on the 3/8 inch sieve.

- No. 4 sieve: This control allows you to define the cumulative amount of aggregate material (used in the asphalt mixture) that is passing on the #4 sieve.

- No. 200 sieve: This control allows you to define the amount of aggregate material (used in the asphalt mixture) that is passing on the #200 inch sieve.

Note:

The model for determining frequency adjusted viscosity is research grade and not nationally calibrated, while the simple conversion model is nationally calibrated. This option is applicable only for Superpave binders at input levels 1 and 2.

Select HMA Estar Predictive Model

- Select HMA Estar predictive model: This control provides you the option for accounting the effects of loading frequencies when binder G* values are converted to viscosity values. Select True for frequency-adjusted viscosity estimates or False for simple conversion without frequency adjustments.

Reference Temperature

- Reference temperature (deg F): This control allows you to define a baseline temperature, in degrees Fahrenheit, for use in deriving the dynamic modulus mastercurve. The suggested value is 70˚F.

Asphalt Binder

- Asphalt Binder: This control allows you to define the inputs of asphalt binder properties of asphalt concrete material. The controls in the dropdown menu vary with the dynamic modulus input level you selected.

Note:

Once the dynamic modulus input level is selected, the program automatically defines the same input level for asphalt binder properties. Thus, a Level 1 dynamic modulus input selection will result in a Level 1 input selection for asphalt binder properties. Asphalt binder input level cannot be changed independent of the dynamic modulus input level.

Asphalt Binder Levels 1 and 2

You must first select an appropriate binder grading system and then enter the binder properties.

Superpave Performance Grade

Figure 816: Level 1 SuperPave Performance

- Temperature (deg F): This control allows you to define the temperature at which the binder dynamic complex modulus, G*, and phase angle were measured for a given binder.

- **Binder G*:** This control allows you to define the complex shear modulus of the asphalt binder, measured at the test temperature given in the above control.

- Phase angle: This control allows you to define the phase angle measured at the given test temperature.

You should enter at least three values in the above controls, though five is recommended.

Right-Click Menu Options

Right-click on a cell in the table to access the following functionality:

- Copy: This menu item copies the selected value.

- Paste: This menu item pastes the copied value.

- Import MEPDG Binder (.bif) Format: This menu item allows you to import a binder modulus file that was created in using MEPDG.

Penetration/Viscosity Grade

Figure 817: Level 1 Penetration and Viscosity

- Softening point temperature at a viscosity of 13000 Poise: This control allows you to define the softening point temperature of the asphalt binder at a viscosity of 13000 Poise.

- Absolute viscosity of the binder at 140 F: This control allows you to define the absolute viscosity of the asphalt binder at a temperature of 140˚F.

- Kinematic viscosity at 275 F in centistokes: This control allows you to define the kinematic viscosity of the asphalt binder at a temperature of 275˚F.

- Specific gravity of asphalt binder at 77 F: This control allows you to define the specific gravity of the asphalt binder at a temperature of 77˚F.

- Penetration (both temp and penetration value): This control allows you to define the both the temperature, in degrees Fahrenheit, and the corresponding penetration value of the asphalt binder.

- Brookfield viscosity (both temp and viscosity): This control allows you to define the both the temperature, in degrees Fahrenheit, and the corresponding viscosity value of the asphalt binder.

You must enter values for the softening point, specific gravity, absolute viscosity, and kinematic viscosity of the asphalt binder as a minimum. In addition, you may choose to provide either binder penetration or Brookfield viscosity properties or both. PMED allows you to enter penetration or viscosity values for up to six test temperatures.

Asphalt Binder Level 3

The user first selects a binder grading system (radio buttons) and then selects a binder grade from the dropdown menu. (Once a binder grade is selected, the program assumes and displays the typical values of A-VTS parameters for that binder grade).

Figure 818: Level 3 SuperPave

Figure 819: Level 3 Penetration

Figure 820: Level 3 Viscosity

- Grade: These controls allow you to define the grade of the binder. Select one of the following options:

- Superpave Performance Grade: This control allows you to select an appropriate PG binder from the options provided by the binder type dropdown menu.

- Viscosity Grade: This control allows you to select an appropriate viscosity-graded binder from the options provided by the binder type dropdown menu.

- Penetration Grade: This control allows you to select an appropriate penetration-graded binder from the options provided by the binder type dropdown menu.

- A: This control displays the intercept of the ASTM D2493 A-VTS relationship of the binder.

- VTS: This control displays the slope of the ASTM D2493 A-VTS relationship of the binder.

Thermal Properties

- Thermal conductivity (BTU/hr-ft-deg F): This control allows you to define the thermal conductivity of the asphalt concrete material. PMED provides a default value of 0.67.

- Heat capacity (BTU/lb-deg F): This control allows you to define the heat capacity of the asphalt concrete material. PMED provides a default value of 0.23.

Figure 821: Asphalt Thermal

Note:

PMED does not require mix coefficient of thermal contraction inputs for an asphalt concrete base layer. Although the defaults of these inputs may be displayed, PMED does not use them in calculations

Chemically Stabilized Layer

The required inputs for a chemically stabilized layer can be broadly classified as general, strength, and thermal properties. Note that the strength properties required by PMED are different for flexible and rigid pavements.

The chemically stabilized materials include lean concrete, cement stabilized, open graded cement stabilized, soil cement, lime-cement-flyash, and lime treated materials.

You can use the following guidance to decide when a level of material stabilization is adequate to be considered as a chemically stabilized layer or not:

- Chemically stabilized materials that are “engineered” to provide long-term strength and durability should be considered as a chemically stabilized layer (e.g. cement treated, lean concrete, pozzolonic treated). Typically such layers are placed directly under the lowest asphalt layer.

- Lime and/or lime-fly ash stabilized soils could be considered a chemically stabilized layer, if these layers are engineered to provide structural support and have a sufficient amount of stabilizer mixed in with the soil.

- Lime and/or lime-fly ash stabilized soils could be also considered as a material layer that is insensitive to moisture and the resilient modulus or stiffness of these layers can be held constant over time.

- Aggregate or granular base materials treated with small amounts of chemical stabilizers to enhance constructability (e.g. lower the plasticity index, improve the strength) should not be considered as a chemically stabilized layer. They should be considered as an unbound material, and combined with those unbound layers, if necessary (e.g. soil cement). Typically such layers are placed deeper in the pavement structure.

Methods to Populate Inputs

There are three methods for entering data for the Stabilized (Flexible) layer:

- Manual entry

- Import from workspace library

Inputs

General Inputs

- Layer thickness (inch,mm): This control allows you to define the thickness of the stabilized base layer.

- Poisson’s ratio: This control allows you to define the Poisson’s ratio of the chemically stabilized material. Values between 0.15 and 0.35 are typical for chemically stabilized materials.

- Unit weight (\(lb/ft^3\), \(kg/m^3\)): This control allows you to define the weight per unit volume of the stabilized base material. PMED provides a default value of 150 pcf.

Strength Properties

- Elastic/resilient modulus (psi): This control allows you to define the required elastic/ resilient modulus value of chemically stabilized materials.

- Minimum elastic/resilient modulus (psi): This control allows you to define the minimum modulus of chemically stabilized material that represents deteriorated condition under increased levels of fatigue damage. This input is required only for flexible pavements with a chemically stabilized layer placed directly under the AC layer. PMED will not display this control for other pavement types.

- Modulus of Rupture (psi): This control allows you to define the modulus of rupture of chemically stabilized material. The 28-day value is used for design. This input is required only for flexible pavements with a chemically stabilized layer placed directly under the AC layer. PMED will not display this control for other pavement types.

Note:

These inputs can be determined either through laboratory testing, correlations, or based on agency experience and historical records for levels 1, 2 and 3, respectively.

Thermal Properties

- Thermal conductivity (BTU/hr-ft-deg F): This control allows you to define the thermal conductivity of the chemically stabilized material. PMED provides a default value of 1.25 Btu/(ft)(hr)(˚F).

- Heat capacity (BTU/lb-deg F): This control allows you to define the heat capacity of the chemically stabilized material. PMED provides a default value of 0.28 Btu/(lb)(˚F).

Non-stabilized unbound base

Non-stabilized materials include AASHTO soil classes A-1 through A-3, as well as those commonly defined in practice as crushed stone, crushed gravel, river gravel, permeable aggregate, and cold recycled asphalt material (includes millings and in-place pulverized material).

Inputs required for non-stabilized materials include physical and engineering properties such as dry density, moisture content, hydraulic conductivity, specific gravity, soil-water characteristic curve (SWCC) parameters, classification properties, and the resilient modulus.

Methods to Populate Inputs

There are two methods for entering data: - Manual entry - Import from workspace library

Inputs

General Inputs

- Layer thickness (in, mm): This control allows you to define the thickness of the selected layer.

- Poisson’s ratio: This control allows you to define the Poisson’s ratio of the unbound material. PMED provides a default value of 0.35.

- Coefficient of lateral earth pressure (k0): This control allows you to define the pressure that the unbound material exerts in the horizontal plane. PMED provides a default value of 0.5.

Resilient Modulus

Resilient Modulus (psi, MPa): This control allows you to define the level of inputs for resilient modulus of the unbound material. This control also allows you to define the resilient modulus or the other material properties that correlate with the resilient modulus. PMED displays the default value (Level 3) for the selected material class. Click on the Resilient Modulus control to modify the default value and/or input level.

- Input Level: This control allows you to define the level of inputs for the non-stabilized material. You can select one of the following options:

- Level 1: PMED does not provide Level 1 inputs option for resilient modulus of non-stabilized materials.

- Level 2: This option allows you to define the resilient modulus directly or using its correlations with soil index and strength properties. This level of input is considered as Level 2 in the AASHTO Manual of Practice.

- Level 3: This option allows you to override the default resilient modulus value (Level 3) of the non-stabilized material.

- Analysis Types: These controls allow you to define how PMED accounts for seasonal variations (freezing, thawing and moisture) in the resilient modulus calculations. Select one of the following options:

- Modify input values by temperature/moisture: This option allows you to define a single resilient modulus value. You can also input a single value of the selected soil index or strength property that is converted by PMED into a resilient modulus value. PMED incorporates the effects of seasonal variations on the single resilient modulus value you define.

- Monthly representative values: This option allows you to define the resilient modulus throughout the year. You can input a single value of resilient modulus (or the selected soil index or strength property) for each month of a year. By selecting this option, you make PMED use the inputs you provide directly for seasonal variations without making internal adjustments. This option is available only for Level 2 inputs.

- Annual representative values: This option allows you to define a fixed resilient modulus for an entire year. You can input a single value of resilient modulus (or the selected soil index or strength property) that is representative for an entire year. PMED does not incorporate the effects of seasonal variations on the single resilient modulus value you define.

- Correlation Methods to estimate Resilient Modulus: This control allows you to select how to estimate the resilient modulus using one of the following options:

- Resilient modulus (psi, MPa)

- California Bearing Ratio (CBR) (percent) R-value

- Layer Coefficient-ai

- Dynamic Cone Penetrometer (DCP) Penetration (in./blow, mm/blow)

- Plasticity Index (PI) and Gradation (i.e., Percent Passing No. 200 (0.075mm) sieve)

- Input Entry Table: This control allows you to define the values for resilient modulus or the selected soil index and strength property.

Aggregate Gradation and other engineering properties

The aggregate gradation dialog box allows you to define the particle size distribution, Atterberg limits, specific gravity, water content, maximum dry density, saturated hydraulic conductivity and the SWCC parameters of non-stabilized materials. A description of the available inputs are summarized below.

- Sieve Size Table: This table allows you to define the percentage of non-stabilized material passing a variety of sieve sizes.

- Sieve Opening Size (in, mm): This column lists the applicable sieve sizes.

- Percent Passing: This column allows you to define the percentage of non-stabilized material passing a given sieve size. You are not required to define the percent passing for each sieve size. However, you are required to enter values for a minimum of 3 sieve sizes including No. 200 sieve.

- Liquid Limit This control allows you to define the liquid limit of the non-stabilized material.

- Plasticity Index: This control allows you to define the plasticity index for non-stabilized material.

- Is Layer Compacted?: Enable this control to indicate that the layer is compacted. Typically non-stabilized materials used in the base and subbase layers are compacted in place during construction. Disable this control to indicate that the layer is not compacted.

- Maximum dry unit weight (\(lb/ft^3\), \(kg/m^3\)): PMED internally computes the maximum dry unit weight of the non-stabilized material. This control allows you to override the internally computed value by enabling the check box. Click the check box to enable/disable this control.

- Saturated hydraulic conductivity (ft/hr, m/hr): PMED internally computes the saturated hydraulic conductivity of the non-stabilized material. This control allows you to override the internally computed value by enabling the check box. Click the check box to enable/disable this control.

- Specific gravity of solids: PMED internally computes the specific gravity of the non-stabilized material. This control allows you to override the internally computed value by enabling the check box. Click the check box to enable/disable this control.

- Optimum gravimetric water content (%): PMED internally computes the moisture content of the non-stabilized material at which maximum dry density is achieved. This control allows you to override the internally computed value by enabling the check box. Click the check box to enable/disable this control.

- User-defined Soil Water Characteristic Curve (SWCC): PMED internally computes the coefficients (af, bf, cf, and hr) of the soil water characteristic curve. This control allows you to override the internally computed value by enabling the check box. Click the check box to enable/disable this control.

Note:

PMED internally computes the values of the following properties based on the inputs for Gradation, Liquid Limit, Plasticity Index and Is Layer Compacted. The computed values are based on the defaults initially displayed on the input screen. However, if you choose to modify the default values, you are required to click outside the input screen for the program to update the internally computed values.

Note:

Input compatibility: It is essential that the values entered for water content, maximum dry unit weight are compatible. If the value water content entered represents optimium conditions, then the maximum dry unit weight at optimum conditions should also be entered.

Subgrade

Subgrade materials include AASHTO soil classes A-1 through A-3, as well as those commonly defined in practice as crushed stone, crushed gravel, river gravel, permeable aggregate, and cold recycled asphalt material (includes millings and in-place pulverized material).

Inputs required for subgrade materials include physical and engineering properties such as dry density, moisture content, hydraulic conductivity, specific gravity, soil-water characteristic curve (SWCC) parameters, classification properties, and the resilient modulus.

Methods to Populate Inputs

There are two methods for entering data: - Manual entry - Import from workspace library

Inputs

General Inputs

- Layer thickness (in, mm): This control allows you to define the thickness of the selected layer.

- Poisson’s ratio: This control allows you to define the Poisson’s ratio of the subgrade material. PMED provides a default value of 0.35.

- Coefficient of lateral earth pressure (k0): This control allows you to define the pressure that the unbound material exerts in the horizontal plane. PMED provides a default value of 0.5.

Figure 825: Subgrade Unbound

Resilient Modulus

Resilient Modulus (psi, MPa): This control allows you to define the level of inputs for resilient modulus of the unbound material. This control also allows you to define the resilient modulus or the other material properties that correlate with the resilient modulus. PMED displays the default value (Level 3) for the selected material class. Click on the Resilient Modulus control to modify the default value and/or input level.

- Input Level: This control allows you to define the level of inputs for the subgrade material. You can select one of the following options:

- Level 1: PMED does not provide Level 1 inputs option for resilient modulus of subgrade materials.

- Level 2: This option allows you to define the resilient modulus directly or using its correlations with soil index and strength properties. This level of input is considered as Level 2 in the AASHTO Manual of Practice.

- Level 3: This option allows you to override the default resilient modulus value (Level 3) of the subgrade material.

- Analysis Types: These controls allow you to define how PMED accounts for seasonal variations (freezing, thawing and moisture) in the resilient modulus calculations. Select one of the following options: -Modify input values by temperature/moisture: This option allows you to define a single resilient modulus value. You can also input a single value of the selected soil index or strength property that is converted by PMED into a resilient modulus value. PMED incorporates the effects of seasonal variations on the single resilient modulus value you define. -Monthly representative values: This option allows you to define the resilient modulus throughout the year. You can input a single value of resilient modulus (or the selected soil index or strength property) for each month of a year. By selecting this option, you make PMED use the inputs you provide directly for seasonal variations without making internal adjustments. This option is available only for Level 2 inputs. -Annual representative values: This option allows you to define a fixed resilient modulus for an entire year. You can input a single value of resilient modulus (or the selected soil index or strength property) that is representative for an entire year. PMED does not incorporate the effects of seasonal variations on the single resilient modulus value you define.

- Correlation Methods to estimate Resilient Modulus: This control allows you to select how to estimate the resilient modulus using one of the following options:

- Resilient modulus (psi, MPa)

- California Bearing Ratio (CBR) (percent) R-value

- Layer Coefficient-ai

- Dynamic Cone Penetrometer (DCP) Penetration (in./blow, mm/blow)

- Plasticity Index (PI) and Gradation (i.e., Percent Passing No. 200 (0.075mm) sieve)

- Input Entry Table: This control allows you to define the values for resilient modulus or the selected soil index and strength property.

Figure 826: Subgrade Modulus

Aggregate Gradation and other engineering properties

The aggregate gradation dialog box allows you to define the particle size distribution, Atterberg limits, specific gravity, water content, maximum dry density, saturated hydraulic conductivity and the SWCC parameters of subgrade materials. A description of the available inputs are summarized below.

- Sieve Size Table: This table allows you to define the percentage of subgrade material passing a variety of sieve sizes.

- Sieve Opening Size (in, mm): This column lists the applicable sieve sizes.

- Percent Passing: This column allows you to define the percentage of subgrade material passing a given sieve size. You are not required to define the percent passing for each sieve size. However, you are required to enter values for a minimum of 3 sieve sizes including No. 200 sieve.

- Liquid Limit This control allows you to define the liquid limit of the subgrade material.

- Plasticity Index: This control allows you to define the plasticity index for subgrade material.

- Is Layer Compacted?: Enable this control to indicate that the layer is compacted. Typically subgrade materials used in the base and subbase layers are compacted in place during construction. Disable this control to indicate that the layer is not compacted.

- Maximum dry unit weight (\(lb/ft^3\), \(kg/m^3\)): PMED internally computes the maximum dry unit weight of the subgrade material. This control allows you to override the internally computed value by enabling the check box. Click the check box to enable/disable this control.

- Saturated hydraulic conductivity (ft/hr, m/hr): PMED internally computes the saturated hydraulic conductivity of the subgrade material. This control allows you to override the internally computed value by enabling the check box. Click the check box to enable/disable this control.

- Specific gravity of solids: PMED internally computes the specific gravity of the subgrade material. This control allows you to override the internally computed value by enabling the check box. Click the check box to enable/disable this control.

- Optimum gravimetric water content (%): PMED internally computes the moisture content of the subgrade material at which maximum dry density is achieved. This control allows you to override the internally computed value by enabling the check box. Click the check box to enable/disable this control.

- User-defined Soil Water Characteristic Curve (SWCC): PMED internally computes the coefficients (af, bf, cf, and hr) of the soil water characteristic curve. This control allows you to override the internally computed value by enabling the check box. Click the check box to enable/disable this control.

Figure 827: Subgrade Sieve

Note:

PMED internally computes the values of the following properties based on the inputs for Gradation, Liquid Limit, Plasticity Index and Is Layer Compacted. The computed values are based on the defaults initially displayed on the input screen. However, if you choose to modify the default values, you are required to click outside the input screen for the program to update the internally computed values.

Note:

Input compatibility: It is essential that the values entered for water content, maximum dry unit weight are compatible. If the value water content entered represents optimium conditions, then the maximum dry unit weight at optimum conditions should also be entered.

Bedrock

A bedrock layer, if present under an alignment, could have a significant impact on the pavement’s mechanistic responses and therefore need to be fully accounted for in design. This is especially true if backcalculation of layer moduli is adopted in rehabilitation design to characterize pavement materials. While the precise measure of the stiffness is seldom, if ever, warranted, any bedrock layer must be incorporated into the analysis.

Inputs

Bedrock

- Layer thickness (in.): The program automatically defines the thickness of the bedrock layer as semi-infinite.

- Poisson’s ratio: This control allows you to define the Poisson’s ratio of the bedrock material. PMED provides a default value of 0.15 for solid, massive and continuous bedrock material and 0.30 for highly fractured, weathered bedrock material.

- Unit weight (pcf): This control allows you to define the weight per unit volume of the bedrock material. PMED uses a default value of 140 pcf.

Strength

- Elastic/resilient Modulus (psi): This control allows you to define the modulus of the bedrock layer. PMED provides a default value of 750,000 psi for solid, massive and continuous bedrock material and 500,000 psi for highly fractured, weathered bedrock material.

Figure 829: Bedrock Strength

Design and Layer Properties

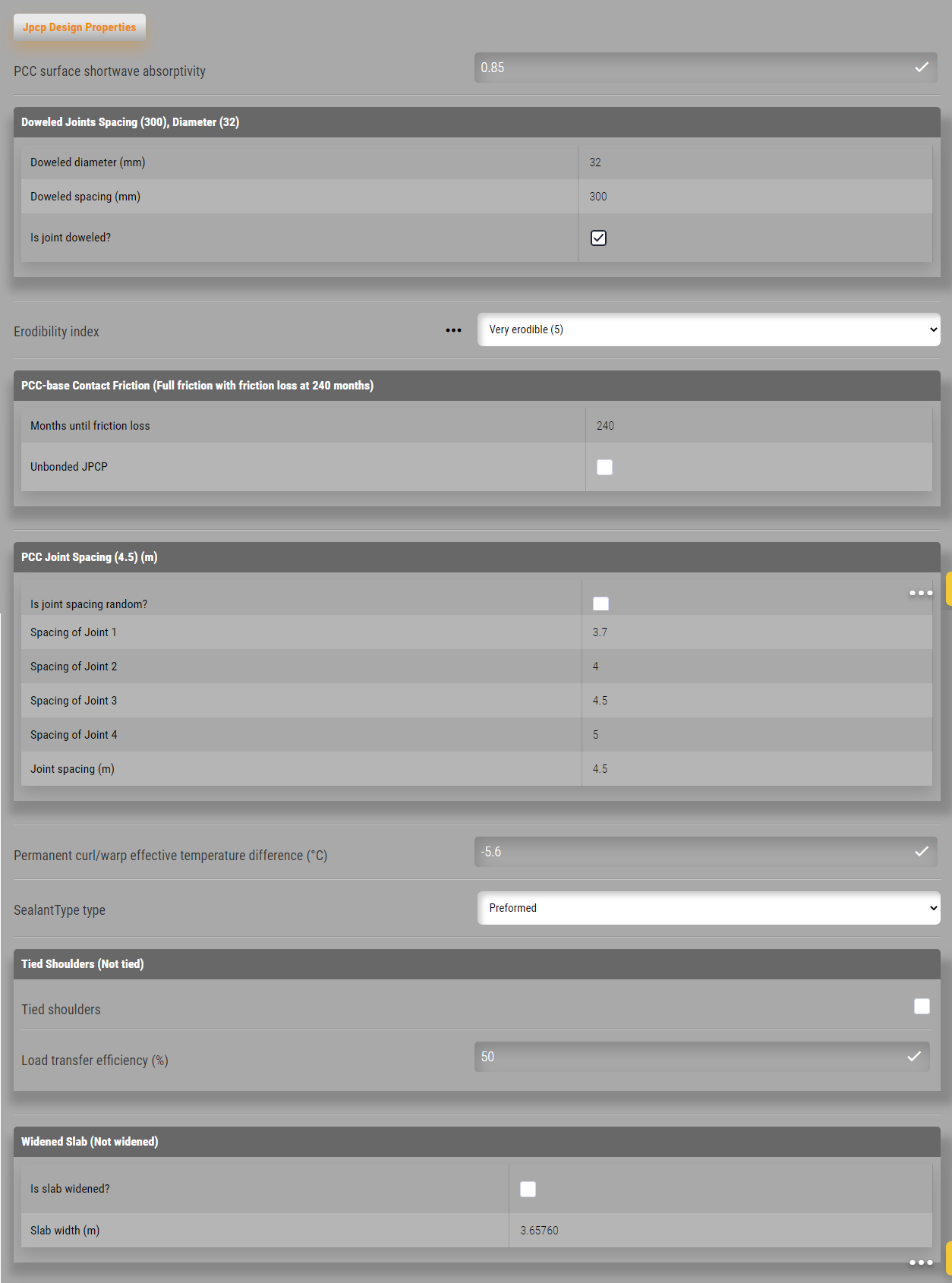

JPCP Design Properties

JPCP design features and construction practices influence long-term performance. The common design features that are considered by PMED include widened PCC slabs, joint spacing, shoulder type (tied vs untied PCC or asphalt concrete), presence and size of dowel bars used for transverse join tload transfer, dowel bar spacing, base type and erodibility, (chemically stabilized, asphalt stabilized, and non stabilized aggregate). Construction practices include PCC curing method (curing compound vs. wet curing), permanent curl/warp effective temperature difference in the PCC, PCC/base layer friction loss age, initial smoothness, and so on. Some of these design features and construction practices have been described in previous sections.

PCC surface shortwave absorptivity: This control allows you to define the fraction of solar energy (sunshine) at the PCC surface that is absorbed by the PCC. PMED presents a default value of 0.85. You can override this default.

Doweled joint spacing (ft): This control allows you to define the transverse joint load transfer mechanism.

- Dowel diameter (in.): This option allows you to define the diameter of the dowel bars used for load transfer across the transverse joint. A value of zero implies there are no dowel bars and load transfer is primarily through aggregate interlock.

- Dowel spacing (in.): This option allows you to define the center-to-center distance between adjacent dowel bars if used for load transfer across transverse joints.

- Is joint doweled?: This control allows you to select whether transverse joint load transfer mechanism is through the dowel bars:

- True: Selecting this option implies transverse joint load transfer mechanism is through dowel bars.

- False: Selecting this option implies transverse joint load transfer mechanism is through aggregate interlock only.

Erodibility index: This control allows you to select the resistance of the base course to erosion, using an index on a scale of 1 to 5. Material erosion resistance is determined both by its strength and durability. PMED allows you to select one of the following options:

- Extremely erosion resistant: Select an erodibility index of 1 for extremely erosion resistant base materials such as asphalt concrete and lean concrete materials.

- Very erosion resistant: Select an erodibility index of 2 for very erosion resistant base materials such as asphalt treated and cement treated materials.

- Erosion resistant: Select an erodibility index of 3 for erosion resistant base materials.

- Fairly erodible: Select an erodibility index of 4 for fairly erodible base materials such as weakly stabilized aggregate materials and subgrade soils.

- Very erodible: Select an erodibility index of 5 for very erodible base materials such as unstabilized subgrade soils.

PCC-base contact friction: The interface between the underlying base and PCC slab is modeled with or without full friction for JPCP design. PMED allows you to (1) determine whether or not the PCC slab/base interface has full friction at construction and (2) how long full friction will be available at the interface if present after construction. This control displays options available for modeling PCC slab/base interface condition.

- Months until friction loss: This option allows you to define the number of months after which full friction at the PCC slab/base interface is lost. The AASHTO Manual of Practice presents recommendations according to base material type. PMED allows for a range of 0 to 1200 months.

- Unbounded JPCP: This option allows you to select whether or not there is full friction at the PCC slab/base interface after construction. PMED allows you to select one of the following options:

- True: Selecting this option implies there is full friction at the PCC slab/base interface after friction.

- False: selecting this option implies there is relatively little to no friction at the PCC slab/base interface after friction.

PCC joint spacing (ft): This control allows you to define whether transverse joints of the trial design are uniformly or randomly spaced.

- Is joint spacing random? This control allows you to define whether transverse joints are uniformly spaced or randomly spaced. PMED allows for the following options:

- True: Selecting this option implies transverse joint are randomly spaced.

- Spacing of joint 1: This option allows you to define the length of the first PCC slab.

- Spacing of joint 2: This option allows you to define the length of the second PCC slab.

- Spacing of joint 3: This option allows you to define the length of the third PCC slab.

- Spacing of joint 4: This option allows you to define the length of the fourth PCC slab.

- False: Selecting this option implies transverse joint are uniformly spaced.

- Joint spacing: This option allows you to define average length of all the PCC slabs.

Permanent curl/warp effective temperature difference (deg F): This input describes the combined effect of (1) PCC built-in temperature gradient at time of set, (2) effective gradient of moisture warping in the PCC (dry on top and wet on bottom), (3) long term creep of the PCC slab, and (4) settlement of the PCC into the base. It is defined in terms of equivalent temperature difference. PMED presents the default value of -10 °F which was established as optimum to minimize error between measured and predicted cracking and measured and predicted faulting during the national calibration.

Sealant type: This control allows you to select the sealant type applied at the transverse joints. PMED allows you to choose from the following sealant types: preformed, liquid, and silicone.

Note:

Sealant type is an input to the JPCP transverse joint spalling model. Spalling is a key input for JPCP smoothness prediction.

Tied shoulders: This control allows you to select whether or not to use tied PCC shoulders. PMED allows you to select one of the following options:

True: Selecting this option implies the use of tied PCC shoulders.

False: Selecting this option implies the use of other shoulder types such as PCC (without tiebars), asphalt concrete, or gravel shoulders.

Load transfer efficiency (%): This option allows you to define the long-term or terminal deflection LTE at the lane (PCC outer lane slab) to PCC shoulder longitudinal joint. PMED provides a default value of 50 percent. Typical long-term LTE are 50 to 70 percent for monolithically constructed tied PCC shoulder and 30 to 50 percent for separately constructed tied PCC shoulder.

Widened slab: This control displays if the PCC slabs are widened. Note that the typical JPCP PCC slab width is 12-ft.

Is slab widened? This control allows you to select whether or not the JPCP PCC slab width is widened. PMED allows you to select one of the following options:

- True: Selecting this option implies that the PCC slabs are widened (slab width is greater than 12-ft, typically 13- or 14-ft)

- False: Selecting this option implies that the PCC slabs are not widened (slab width is 12-ft)

Slab width (ft.): This option allows you to define the slab width. Note slab width is defined only when widened PCC slab option is applied. Otherwise, PMED assumes a standard 12-ft slab width.

PCC-base contact friction: The interface between the underlying base and PCC slab is modeled with or without full friction for JPCP design. PMED allows you to (1) determine whether or not the PCC slab/base interface has full friction at construction and (2) how long full friction will be available at the interface if present after construction. This control displays options available for modeling PCC slab/base interface condition.

PCC-Base full-friction contact: This option allows you to select whether or not there is full friction at the PCC slab/base interface after construction. PMED allows you to select one of the following options:

- True: Selecting this option implies there is full friction at the PCC slab/base interface after friction.

- False: selecting this option implies there is relatively little to no friction at the PCC slab/base interface after friction.

- Months until friction loss: This option allows you to define the number of months after which full friction at the PCC slab/base interface is lost. The AASHTO Manual of Practice presents recommendations according to base material type. PMED allows for a range of 0 to 1200 months.

Figure 830: JPCP Design Properties

JPCP Rehabilitation

This screen allows you to provide the required PMED inputs indicative of the existing level of distresses in a restoration or rehabilitation design.

The inputs enable PMED to estimate damage based on the condition of the existing pavement. The extent of repairs undertaken at the time of rehabilitation is used to adjust future performance predictions as needed.

Ways to Access this Interface

Open a rehabilitation project with a JPCP layer and select JPCP Rehabilitation in the Layer control.

Figure 831: JPCP Rehabilitation

Ways to Enter Inputs

There are three methods for entering data for the PCC layer:

- Manual entry

- Import from file

- Import from database

Populating the Inputs in this Interface

JPCP Rehabilitation

Slabs distressed/replaced before restoration (%): This control allows you to define the percentage of cracking in slabs before the restoration or rehabilitation. This is essentially the total percentage cracking in the slabs and includes all cracks that were previously.

Slabs repaired/replaced after restoration (%): This option allows you to define the percentage of slabs that were repaired during the restoration or rehabilitation process. The difference between the slabs distressed and slabs replaced is the percentage of slabs that are still cracked after restoration.

Foundation Support

Modulus of subgrade reaction, or k-value, is a soil support parameter. The static k-value is determined from the plate load test and is a measure of the pressure applied on the soil for a unit deformation monitored using a standard size plate. Dynamic k-value is determined through deflection testing and backcalculation. PMED requires dynamic k-value.

Ways to Access this Interface

Open a rehabilitation project with a foundation layer and select Foundation Support in the Layer control.

Figure 832: Foundation Support

Ways to Enter Inputs

There are three methods for entering data for the sandwiched granular layer:

• Manual entry • Import from file • Import from database

Modulus of Subgrade Reaction

• Modulus of subgrade reaction: This control displays whether the modulus of subgrade reaction is calculated internally by PMED or user-defined.

• Is modulus of subgrade reaction measure?: Select True to define the modulus of subgrade reaction (k-value) and the month of the year it was measured. Select False to allow PMED to compute this value.

• Dynamic modulus of subgrade reaction (psi/in.): This control allows you to define the dynamic k-value.

• Month modulus of subgrade reaction measured: This control allows you to define the month of the year when the dynamic k-value was measured.

Structural Response

PMED’s structural model analyzes pavement structure, accounts for discontinuities in that structure, and analyzes the effects of environment and traffic on that structure.

PMED produces the structure response outputs as intermediate files:

Horizontal tensile stresses at the top of PCC Slab are stored in the file “_StressTop.csv”.

Horizontal tensile stresses at the bottom of PCC Slab are stored in the file “_StressBot.csv”.

Corner deflections under wheel loading and due to slab curling and shrinkage warping are stored in the file “_Deflection.csv”. The information contained in both files is as follows:

Year

Age (month)

PCC modulus of rupture (psi)

PCC elastic modulus (million psi)

Thermal gradient (˚F)

Load (kips)

Stress (psi)

Axle type (for stresses at the bottom of PCC slab)

Axle spacing (for stresses at the top of PCC slab)

Corner deflection under wheel loading (in.)

Corner deflection due to slab curling and shrinkage warping (in.) These files are located in the project folder where is the project file is stored.

PMED produces several intermediate files that contain a wide range of calculated output parameters. The contents of some of these files are described at http://www.me-design.com.

Calibration Factors

PCC Restoration Calibration Factors

The Calibration Factors section of Pavement ME Design allows you to specify values for both the current project and for Pavement ME Design as a whole. The variables to be defined depend on the types of pavement you select.

Note:

MEPDG performance prediction models were originally developed in US Customary units. Therefore, all parameters in the performance prediction models, including calibration factors, are in US Customary unit.

Project Specific Calibration Factors

1.To modify the calibration for the current project only, click the plus sign (+) next to Project Specific Calibration Factors under the current project in the Explorer tree. The Project Specific Calibration Factors are highlighted in red in the Explorer graphic on this page. 2.Select the type of Project Specific Calibration Factors that matches the currently active project. For Flexible Pavement Design, double-click New Flexible. 3.You can also access Project Specific Calibration Factors by selecting New Flexible Pavement-Calibration Settings from the Layer drop-down box. 4.The application displays the calibration factors for the current project. All variables are explained in the following section.

PMED Calibration Factors

The PMED Calibration Factors folder, located at the bottom of the Explorer pane, contains settings to modify the default design calibration settings for the entire application. The PMED Calibration Factors are highlighted in blue in the graphic above.

Do not make changes to any data you access through the PMED Calibration Factors section unless you intend to change default settings for the entire application.

New Rigid Calibration Factors include:

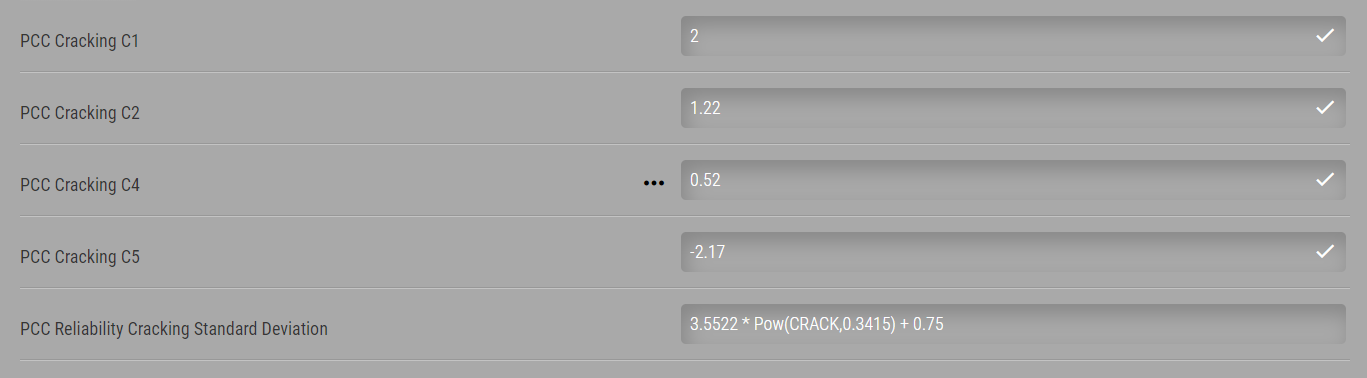

PCC Cracking

- PCC Cracking C1: JPCP repetitive-loading or fatigue damage value for C1.

- PCC Cracking C2: JPCP repetitive-loading or fatigue damage value for C2.

- PCC Cracking C4: JPCP cracking value for C4.

- PCC Cracking C5: JPCP cracking value for C5.

- PCC Reliability Cracking Standard Deviation: Dispersion from the average cracking value for JPCP.

Figure 833: PCC Cracking

Note:

Restore Rigid PCC Cracking calibration settings apply only for JPCP Restoration.

PCC Faulting

- PCC Faulting C1: Value for the elevation or depression of a C1 PCC slab in relation to an adjoining slab.

- PCC Faulting C2: Value for the elevation or depression of a C2 PCC slab in relation to an adjoining slab.

- PCC Faulting C3: Value for the elevation or depression of a C3 PCC slab in relation to an adjoining slab.

- PCC Faulting C4: Value for the elevation or depression of a C4 PCC slab in relation to an adjoining slab.

- PCC Faulting C5: Value for the elevation or depression of a C5 PCC slab in relation to an adjoining slab.

- PCC Faulting C6: Value for the elevation or depression of a C6 PCC slab in relation to an adjoining slab.

- PCC Faulting C7: Value for the elevation or depression of a C7 PCC slab in relation to an adjoining slab.

- PCC Faulting C8: Value for the elevation or depression of a C8 PCC slab in relation to an adjoining slab.

- PCC Reliability Faulting Standard Deviation: Dispersion from the average elevation/depression value of a PCC slab in relation to an adjoining slab.

Figure 834: PCC IRI CRCP

Note:

Restore Rigid PCC Faulting calibration settings apply only for JPCP Restoration.

PCC IRI-CRCP

- PCC IRI C1: This control allows you to modify the CRCP International Roughness Index (IRI) value for C1, which is the contribution from punchout.

- PCC IRI C2: This control allows you to modify the CRCP IRI value for C2, which is the contribution from site factors.

- PCC IRI CRCP Std. Dev.: This control allows you to modify the IRI standard deviation for C1 and C2.

Note:

Restore Rigid PCC IRI-CRCP calibration settings do not apply for JPCP Restoration.

PCC IRI-JPCP

- PCC IRI J1: This control allows you to modify the JPCP IRI value for J1, which is the contribution from transverse cracking.

- PCC IRI J2: This control allows you to modify the JPCP IRI value for J2, which is the contribution from joint spalling.

- PCC IRI J3: This control allows you to modify the JPCP IR value for J3, which is the contribution from joint faulting.

- PCC IRI J4: This control allows you to modify the JPCP IRI value for J4, which is the contribution from site factors.

- PCC IRI JPCP Std. Dev.: This control allows you to modify the IRI standard deviation for J1 through J4.

Note:

Restore Rigid PCC IRI-JPCP calibration settings apply only for JPCP Restoration.

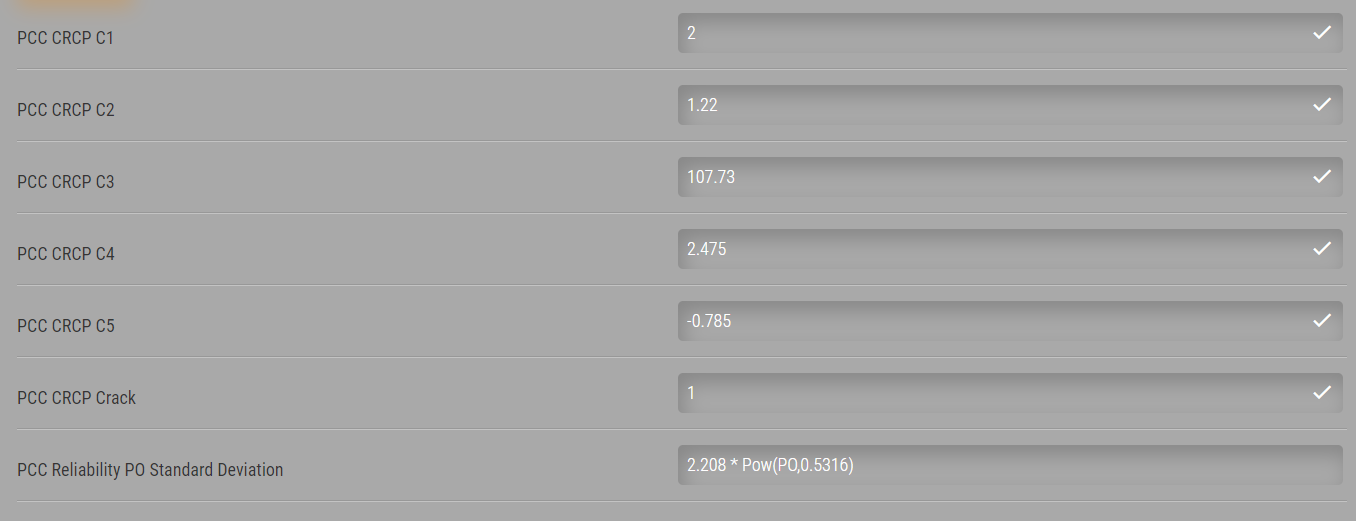

PCC Punchout

- PCC CRCP C1: Broken area of a CRCP C1 slab bounded by closely spaced cracks (usually spaced less than 3 feet).

- PCC CRCP C2: Broken area of a CRCP C2 slab bounded by closely spaced cracks (usually spaced less than 3 feet).

- PCC CRCP C3: Broken area of a CRCP C3 slab bounded by closely spaced cracks (usually spaced less than 3 feet).

- PCC CRCP C4: Broken area of a CRCP C4 slab bounded by closely spaced cracks (usually spaced less than 3 feet).

- PCC CRCP C5: Broken area of a CRCP C5 slab bounded by closely spaced cracks (usually spaced less than 3 feet).

- PCC CRCP Crack: Broken area of a slab bounded by closely spaced cracks.

- PCC Reliability PO Standard Deviation: Dispersion from average of the broken area of a CRCP slab bounded by closely spaced cracks.

Figure 835: PCC IRI CRCP

Note:

Restore Rigid PCC Punchout calibration settings do not apply for JPCP Restoration.